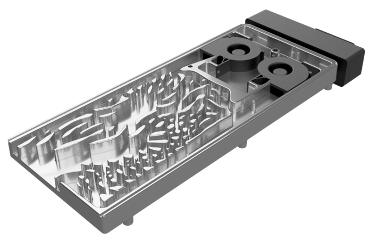

Adequate electric vehicle thermal management is essential for a long battery life, fast charging, fast car acceleration, among many others. Our generative design technology has found its way into this increasingly challenging expert domain. Our software ColdStream will help you during every phase of the cooling design process - from first designs to virtual testing and detailed analysis.

Talk to an expertEmail me this info

.webp)

Forget about tedious trial-and-error cycles and time-consuming manual interventions. Generative design offers a completely new design cycle handling that effectively reduces design cycles by up to 80%. Maximizing acceleration, minimizing mass, maximizing lifespan, or optimizing the design cycle are only is only a few clicks away.