The thermal and flow optimization process enabled by Diabatix's topology optimization software and driven by AI results in optimal designs and performances beyond human imagination.

Topology optimization (TO) is a mathematical method that optimizes material usage and layout within a given design space for a given set of loads, boundary conditions, and constraints to maximize the system's performance.

Use topology optimization to leverage generative design to explore, test, and validate complex design iterations in an effective and efficient way and at scale.Whether it is for automotive, high-performance computing, consumer goods or any other product, generative design can help you push the boundaries of thermal design to new limits.

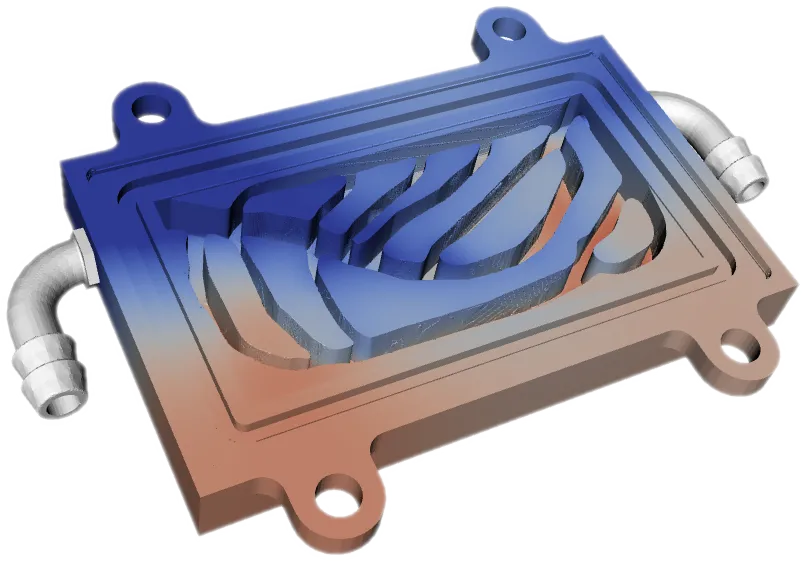

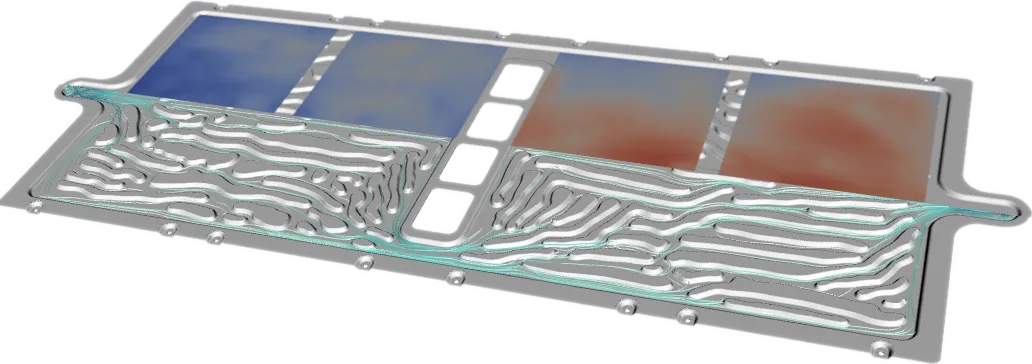

Use topology optimization to design for temperature uniformity and minimal thermal resistance for a given pressure drop constraint and sheet metal forming manufacturing.

Use topology optimization to minimize the temperatures of your power electronics modules containing IGBTs, MOSFETs or any other temperature-sensitive components.

Control the temperature of CPUs, GPU, laser diodes, and any other high-power density electronics component to extend its lifetime with topology optimization.

Minimize thermal resistance to maximize acceleration of your next-generation electric motors with topology optimization from Diabatix.

Generative design through thermal topology optimization is highly adaptable, providing a powerful tool for engineers to optimize their thermal management strategies.

Topology optimization uses advanced mathematical algorithms to design thermal systems through computation efficiently.

Automating the design process reduces the manual work required by thermal design engineers, allowing them to focus on more complex design aspects.

Topology optimization can enhance thermal performance and efficiency by optimizing the topology of thermal components.

This can help to reduce the risk of overheating and increase the lifespan of the device or system.

Topology optimization can accelerate the thermal design process by generating optimized designs that meet the desired performance requirements.

This can reduce the design cycle time and improve the time-to-market for new products, allowing companies to stay ahead of their competitors.