In the world of today's technology, electronic devices have become an integral part of our daily lives. From smartphones and laptops to industrial machinery and power electronics, these devices generate significant amounts of heat during operation. Excessive heat can adversely affect their performance, leading to reduced efficiency and even permanent damage. To tackle this issue, engineers and designers employ various cooling techniques, with one of the most effective being pin fin heat sinks. This article delves into the numerous applications of pin fin heat sinks and how they can enhance thermal management for optimal device performance.

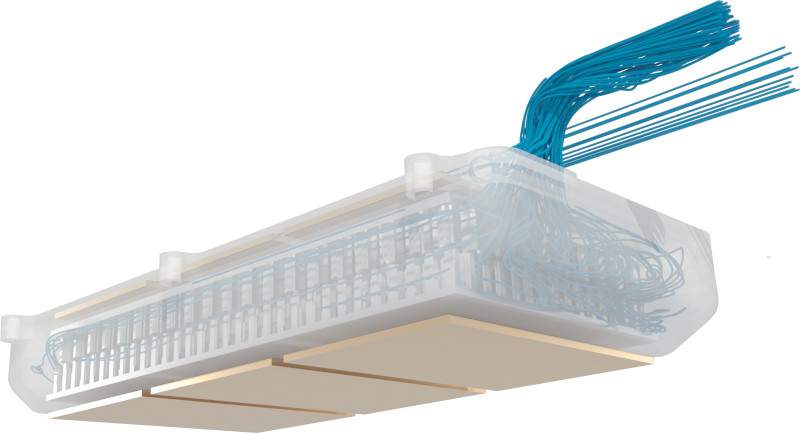

Understanding Pin Fin Heat Sinks

A pin fin heat sink is a thermal management solution used to dissipate heat from electronic components. These heat sinks consist of an array of thin, elongated pins that protrude from a base plate. The design maximizes surface area and promotes efficient heat transfer through convection. As heat from the electronic component travels through the pins, it dissipates into the surrounding air, cooling the device.

Pin Fin Heat Sink Applications

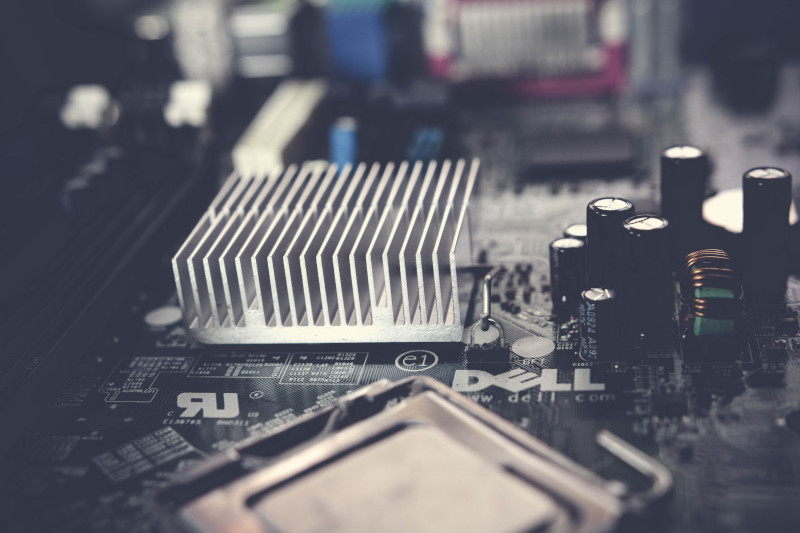

1. Electronic Devices

Pin fin heat sinks find extensive applications in consumer electronic devices, such as laptops, desktop computers, gaming consoles, and smartphones. As these devices continue to push the boundaries of processing power, they generate more heat, making effective thermal management essential for reliable performance. Pin fin heat sinks dissipate heat, ensuring that the devices operate optimally even during prolonged usage.

2. LED Lighting

The widespread adoption of light-emitting diodes (LEDs) for lighting solutions necessitates robust thermal management. LEDs are sensitive to temperature variations, and excess heat can shorten their lifespan and impact light output. Pin fin heat sinks for LED lighting offer a compact and efficient solution to dissipate heat, enhancing overall longevity and performance.

3. Automotive Electronics

Modern vehicles are equipped with a wide range of electronics, from information-entertainment systems and navigation units to engine control modules. These automotive electronics operate in harsh conditions, including high temperatures. Implementing pin fin heat sinks in such systems ensures that heat is efficiently dissipated, preventing overheating and potential system failures.

4. Power Electronics

Power electronic devices, including inverters, rectifiers, and voltage regulators, play a crucial role in various industries. They convert and control electrical power, but this process generates substantial heat. Pin fin heat sinks prove to be a solution for these applications, maintaining the optimal operating temperature of power electronics, leading to enhanced efficiency and reliability.

Watch the on-demand webinar: Choosing the correct heat sink

5. Renewable Energy Systems

Renewable energy sources, such as solar panels and wind turbines, have gained popularity for sustainable power generation. These systems often include power electronics to manage the energy flow and convert it into usable electricity. Pin fin heat sinks help maintain the efficiency of these power electronics, ensuring a steady and reliable output.

6. Industrial Machinery

In industrial settings, machinery and equipment operate under demanding conditions. These machines' high power and continuous operation lead to significant heat generation. Employing pin-fin heat sinks in industrial machinery enhances their reliability and extends their operational life, contributing to increased productivity and reduced downtime.

Advantages of Pin Fin Heat Sinks

- Efficient Heat Dissipation: Pin fin heat sinks offer an excellent surface-to-volume ratio, facilitating efficient heat dissipation, even in compact spaces.

- Compact Design: Their compact design makes them suitable for various electronic devices and tight spaces.

- Lightweight: Pin fin heat sinks are lightweight, ensuring they don't add unnecessary bulk to electronic devices.

- Cost-Effective: These heat sinks are cost-effective to manufacture, making them an economical solution for thermal management.

- Durability: Made from materials like aluminum or copper, pin fin heat sinks boast excellent durability and corrosion resistance.

- Customization: Engineers can tailor the design and dimensions of pin fin heat sinks to meet specific application requirements.

Do you know that ColdStream can automatically select the best pin-fin heat sink? Learn more here.

Conclusion

Pin fin heat sinks have proven to be indispensable in an array of applications, providing efficient thermal management for electronic devices, automotive systems, power electronics, and more. With their compact design, cost-effectiveness, and superior heat dissipation capabilities, pin fin heat sinks ensure optimal performance and extended lifespans for various devices and machinery.

Don't hesitate to contact us to learn how ColdStream can help you to overcome your thermal challenges!

.png)

.png)

.png)

.png)